|

MODEL |

SIZE(DN) |

CONNECTION TYPE |

WORKING PRESSURE(MPa) |

TEMPRETURE(℃) |

OUTSIDE SIZE | |||

|

L |

H1 |

H2 |

W | |||||

|

CS11H-CB |

15~25 |

Thread socket welding |

1.6、 2.5、 4.0 |

300 |

155 |

95 |

100 |

- |

|

CS11H-CD |

32 |

270 |

110 |

135 |

172 | |||

|

40 |

280 |

110 |

165 |

172 | ||||

|

50 |

290 |

110 |

165 |

172 | ||||

|

CS41H-B |

15 |

Flange |

1.6、 2.5、 4.0 |

300 |

195 |

97 |

100 |

126 |

|

20 |

195 |

100 |

101 |

130 | ||||

|

25 |

215 |

105 |

105 |

140 | ||||

|

CS41H-D |

25~32 |

Flange |

1.6、 2.5、 4.0 |

300 |

270 |

110 |

135 |

172 |

|

40 |

280 |

115 |

160 |

172 | ||||

|

50 |

290 |

115 |

160 |

172 | ||||

|

CS41H-16F |

50 |

Flange |

1.6 |

300 |

410 |

175 |

175 |

234 |

|

65 |

410 |

175 |

175 |

236 | ||||

|

80 |

430 |

245 |

245 |

260 | ||||

|

100 |

430 |

255 |

255 |

265 | ||||

|

125~150 |

480 |

185 |

311 |

302 | ||||

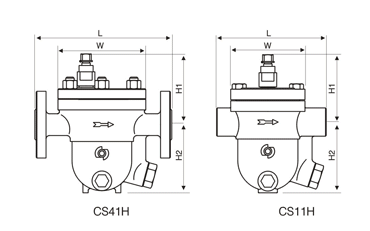

Product drawings

Main parameter dimensions

|

Model |

(DN) |

connection |

(MPa) |

Max Temp. (℃) |

size | |||

|

L |

H1 |

H2 |

W | |||||

|

CS11H-CB |

15~25 |

Thread socket welding |

1.6、 2.5、 4.0 |

300 |

155 |

95 |

100 |

- |

|

CS11H-CD |

32 |

270 |

110 |

135 |

172 | |||

|

40 |

280 |

110 |

165 |

172 | ||||

|

50 |

290 |

110 |

165 |

172 | ||||

|

CS41H-B |

15 |

flange |

1.6、 2.5、 4.0 |

300 |

195 |

97 |

100 |

126 |

|

20 |

195 |

100 |

101 |

130 | ||||

|

25 |

215 |

105 |

105 |

140 | ||||

|

CS41H-D |

25~32 |

flange |

1.6、 2.5、 4.0 |

300 |

270 |

110 |

135 |

172 |

|

40 |

280 |

115 |

160 |

172 | ||||

|

50 |

290 |

115 |

160 |

172 | ||||

|

CS41H-16F |

50 |

flange |

1.6 |

300 |

410 |

175 |

175 |

234 |

|

65 |

410 |

175 |

175 |

236 | ||||

|

80 |

430 |

245 |

245 |

260 | ||||

|

100 |

430 |

255 |

255 |

265 | ||||

|

125~150 |

480 |

185 |

311 |

302 | ||||

|

Model |

DESCRIPTION | |||||

|

Valve type |

CS41H |

|

|

|

Free floating ball type | |

|

CS11H |

|

|

|

|

Free floating ball type | |

|

JX58H |

|

|

|

|

Lever float type | |

|

JX88H |

|

|

|

|

Inverted bucket | |

|

Connection type |

F |

|

|

|

Flange type | |

|

H1 |

|

|

|

Butt welding type | ||

|

H |

|

|

|

Plug in welding | ||

|

S |

|

|

|

Internal screw thread | ||

|

Size |

DN |

|

|

DN15-DN500 | ||

|

pressure |

PN |

|

PN10-PN64 | |||

|

LB |

|

150LB-600LB | ||||

|

K |

|

5K-40K | ||||

|

material |

WCB |

WCB | ||||

|

CF8 |

Stainless steel | |||||

|

Sample: | ||||||

Free-float steam trap

Free floating ball type steam valve structure is simple, and has only one moving part finely ground stainless steel hollow float, float is is opening and closing parts, no wearing parts, long service life, YQ traps with Y series of automatic air exhausting device, very sensitive, can automatically discharge the air, quality work.

Free floating ball type steam trap is the use of Archimedes buoyancy principle, so that the floating ball with the body cavity of the liquid level of the lift and fall, so as to open or close the valve seat drainage.

When starting work, open the manual valve cover on the valve cover, a large number of cold air or non condensing gas in the steam and condensation of water to remove the outside, after closing the gas valve. When hydrophobic valve in the closed state, with the continuation of the time into the valve within the condensed water gradually increased. That is to say, the body cavity surface rise to buoyancy is greater than the sphere of its own weight and valve orifice area force, floating ball valve port is opened, a large number of condensate rapidly discharged into the valve.

In process of drainage, liquid level gradually decreased, due to the cavity pressure distribution is not uniform, the outlet valve at the pressure minimum so that the floating in the liquid level floating ball by the unbalanced force, promote float float to the valve port until to the valve port is closed so far. At this time at the bottom of the body fulcrum resisted the float, the float ball can not continue to fall, the water discharge is stopped. When the liquid level and the valve port to a certain distance, thus forming a water seal to prevent leakage of steam.